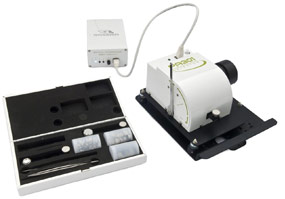

LP1 laser photoacoustic spectroscopy gas analyzer

Overview

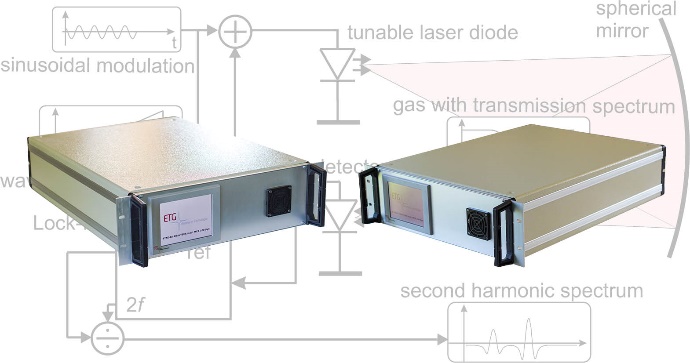

LP1 laser photoacoustic spectrum gas analyzer integrates a semiconductor laser source with high precision and high selectivity tunable controllable spectrum, and a cantilever beam enhanced photoacoustic spectrum technology with wide dynamic range. The zero background noise technology provides high stability without repeated calibration for several months, which makes LP1 an ideal choice for the trace concentration measurement requirements of PPB and PPT.

High sensitivity and a variety of laser light source selection

The photoacoustic spectrum instrument works in an unresonant mode. The signals from two laser sources can be measured simultaneously by using different modulation modes. The resulting photoacoustic signal equivalent quantifies directly the concentrations of different measured gases in a photoacoustic sample chamber.

The modulation wavelength of the laser and the use of low voltage measurement make the analysis of different mixed gases have excellent selectivity. Based on this background noise signal minimization technique, the results of the measurement can be shifted slightly and the calibration period can be extended.

For each suitable laser source, LP1 can be equipped with a wide range of NIR near infrared semiconductor lasers ,and continuously increase the optional laser. Such as quantum cascade lasers (QCL), or near infrared optical parametric oscillators (IR OPO), Continuously increase the gas measurement range and enhance the excellent function of the instrument.

Features

Configurable a variety of laser light according to the operation conditions.

Simultaneous analysis of multicomponent gases

Ppb level measurement

High selectivity

Low sample volume & wide dynamic range

Long calibration period

Free maintenance

Built-in 2 point sampling

Friendly calibration interface

Temperature and pressure fluctuation compensation

Multifunction analysis task

Operation interface pictorial

Results illustrated with pictures and texts

No consumables & no moving parts

Application

Gas impurities

Greenhouse gas (GHG)

Air quality

Occupational safety

Process control

Automated production

Refrigerant leakage

Exhale analysis

Security screening

Natural gas and synthetic gas

Soil analysis

Technology

Semiconductor laser based on photoacoustic spectrum with enhanced cantilever optical microphone

Sample chamber with constant temperature of 50℃

Patented ultra-sensitive optical microphone, based on MEMS cantilever sensor

19”3U industrial housing

Industrial computer with 5.7 "color display

Settable alarm limited detection for the analyzed gas

2GB built-in storage, sufficient for more than 1 year for continuous measurement at the shortest sampling interval.

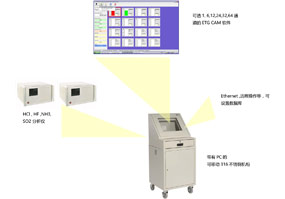

Connect USB port, Ethernet network port and serial port through USB or PC for data transmission

Four gas inlets on the back of the instrument, two customizable as filter device and purification device

Automatically compensates for temperature and pressure fluctuations

Specification

Dimension : 48.4cm W x 13.9cm H x 44cm D (19,1in W x 5,5in H x 17.3in D)

Weight : approximately 13kg

Total sampling volume: 30ml

Pneumatic connection: 6/4mm tube

Electrical connections:

Input voltage: 100~240Vac, 50~60Hz

Input power: 100W

Communication interface: Ethernet,USB,RS232,RS485

Condition

Operation condition:

Temperature: 0°C ~ +45°C

Humidity:<90% RH, no condensation

Pressure: atmospheric pressure

Protection grade: IP20 (IEC 529)

Storage condition:

Temperature range: -20°C ~ +60°C

Sampling condition:

Temperature : 0 ~ +49°C, no condensation

Pressure: 930mbar ~ 1100mbar

Flow rate: approximately 1L/min

Particle: < 1 μm

Features

Response time: typical 5s, customizable

Limited detection : typical ppb level customizable

Dynamic range: Typical 5 orders of magnitude

Repeatability:<1% measurement value

Accuracy : 2% measurement value

Temperature stability: Automatic temperature compensation

Pressure stability: Automatic pressure compensation

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

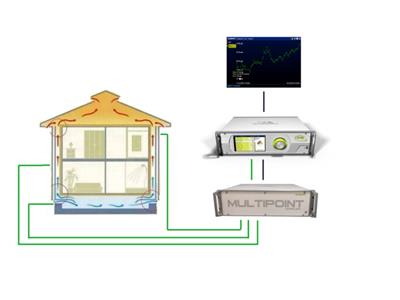

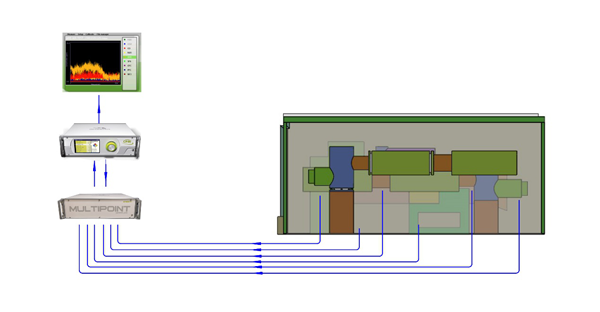

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

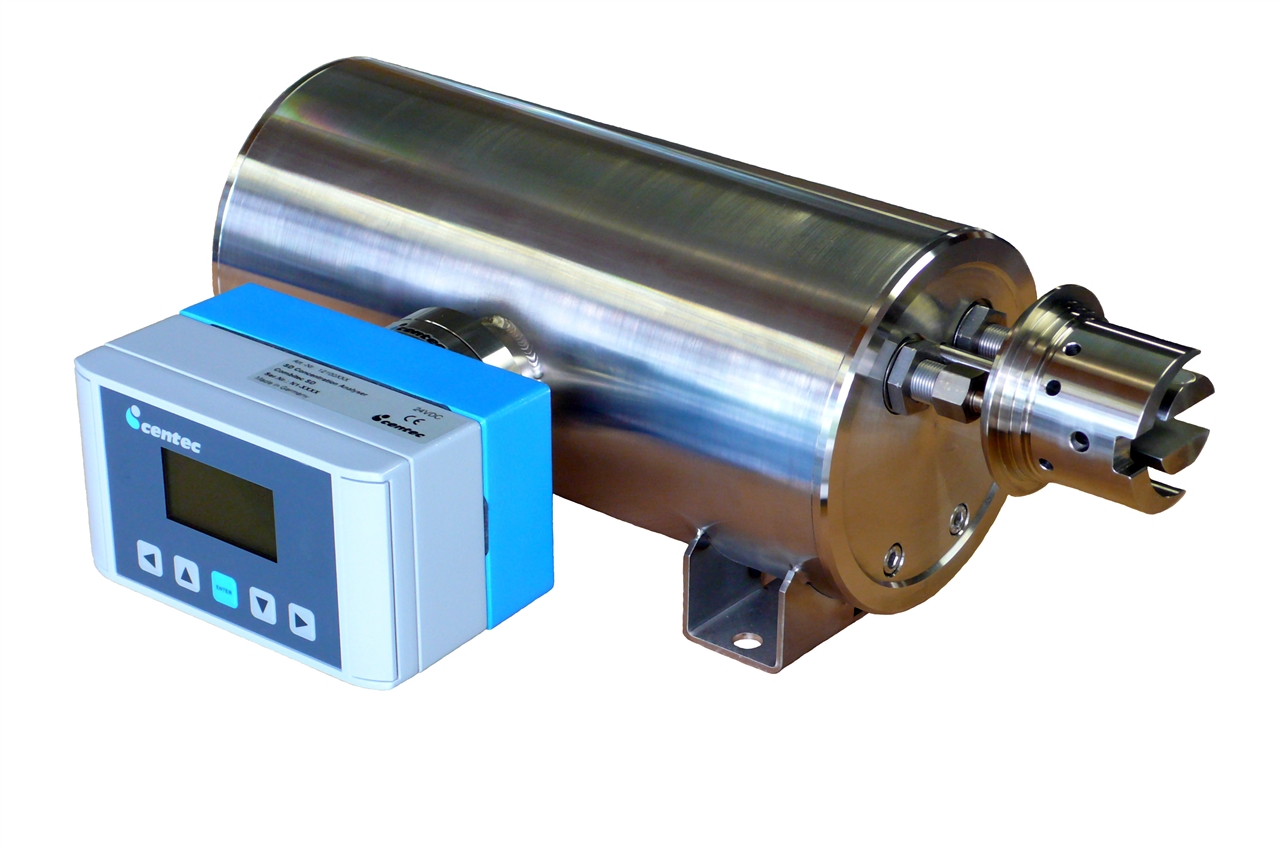

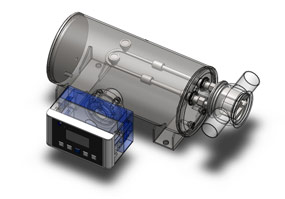

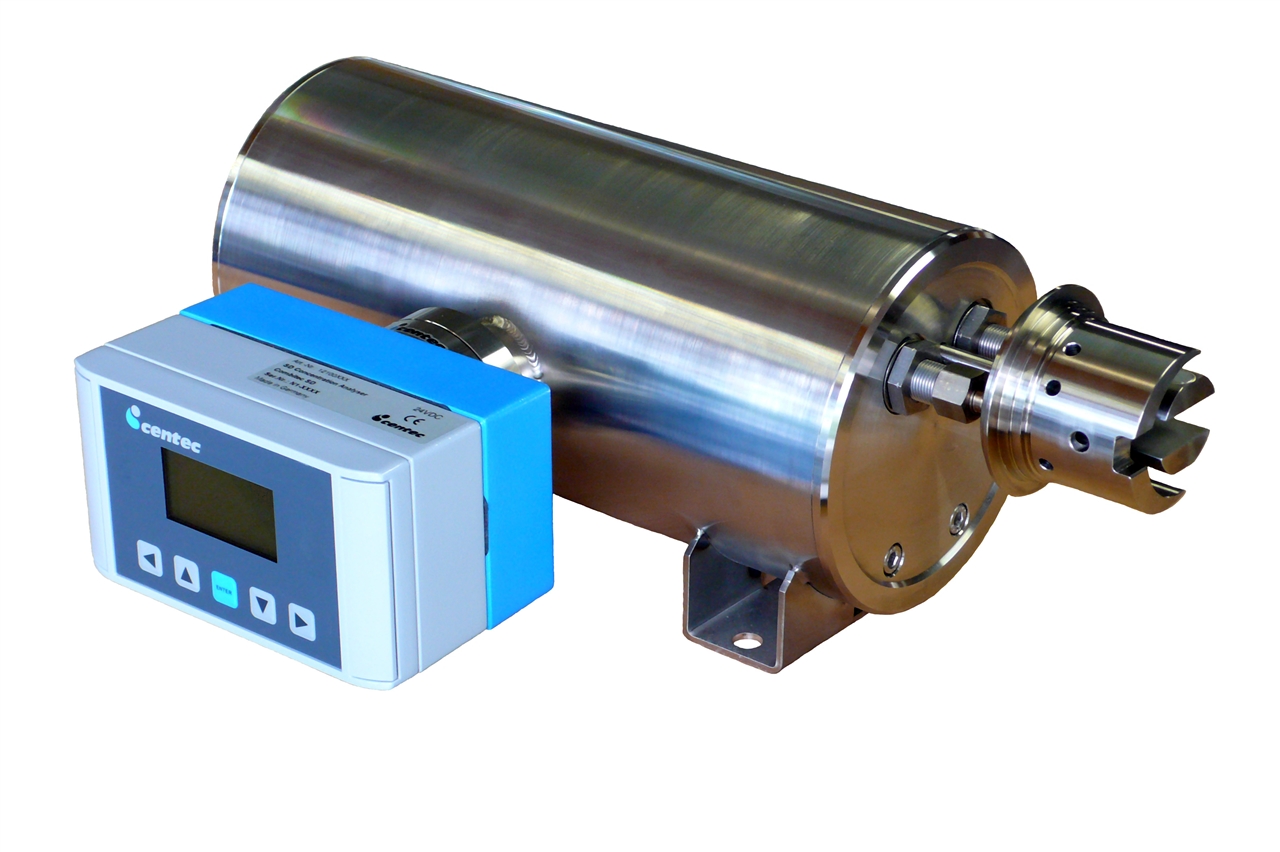

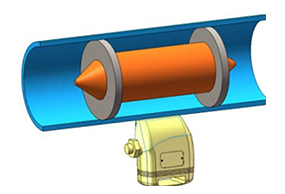

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

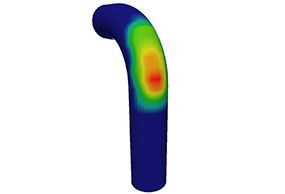

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

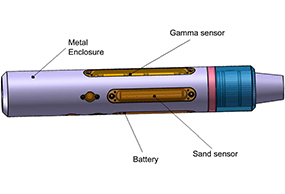

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit